Nouvelles

Success story: E925

🍗↩️ Success story: The E-925 series succeeds on a 680mm radius curve in a conveyor for transporting nuggets in Spain.

Success Story E20: Frozen bread

🥖❄️ Success story: downstream (45º) of frozen bread, to packaging line. Equipped with 50 mm flights made of flexible material.

Success Story E930

🧀♨️Success story of a hot water heat shrinkage system for soft cheeses. Installation of a 300 mm wide E93 curve.

Success story: Series E925 in a cheese factory, Argentina.

Success story in a cheese factory in Argentina. Transport and rotation of product with the E925 Series in polypropylene material. 🧀🧀🧀

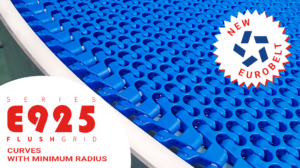

E925 – CURVES WITH MINIMUM RADIUS

EUROBELT modular conveyor belts are made of technical plastics forming a structure of interlocking injection moulded parts in an advanced design whose configuration makes them the ideal support for the transport of food and industrial products. Their modular configuration allows the belt to be made to measure according to requirements. Suitable for applicationsSeguir leyendo

QUICKBELTS

quick-belts.com is the strongest and most stretch-free modular belt on the market. New generation without hinge rods.

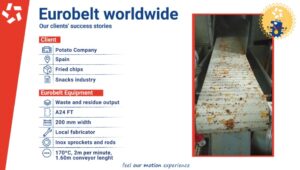

Success story: Residue output from a fryer at 170ºC

🍟🔥Success story in a crisp factory in Spain. This conveyor will remove residues from the fryer at 170ºC. #conveyorbelts #automation #industry

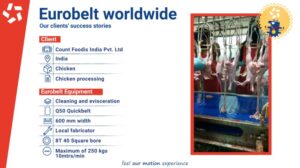

Cas de succès: Poultry Industry in India

🍗🚿Successful case in India of a conveyor equiped with the belt Q50 FT with NSF certificate. https://lnkd.in/dWa_fbq quickbelts.com

Cas de succès: Bande modulaire dans l’industrie du pneumatique

Description du processus La collaboration d’Eurobelt a été proposée pour aider à résoudre une opération de maintenance fréquente nécessaire dans le «Couvercle intermédiaire du convoyeur d’alimentation verticale”. C’est le processus qui prend la feuille de caoutchouc sortant de l’unité de déplacement de wig wag et du détecteur de métal et la place dans le chargeurSeguir leyendo

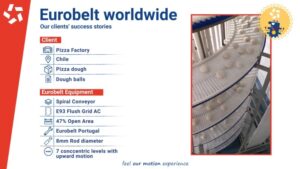

Success story in Chile

Success story of a Chilean installation of a spiral conveyor with 7 levels for pizza dough.