Leaders in modular plastic belts manufacturing

Innovating conveying solutions for demanding customers

Discover our productsMore than 50 years of experience

We are experts in the manufacturing process, assembly and trading of plastic modular belts, offering service at a worldwide level.

about us

Sectors we work with

Commitment in every stage to offer you the best

Manufacturers with

own design

It is supported by an engineering team that is constantly innovating.

Customized advice

Personalized technical support throughout the entire process.

Protocol

of urgency

We are ready for any urgent incident or unexpected event, deliveries between 3-48h.

Service after

sales service

Assistance in installation, as well as maintenance and cleaning.

A modular Belt for each case

Do you need a quick quote?

If you know the specifications of your modular belt, provide us with the data and we will send you a customized proposal.

Latest news

Hygienic design in conveyors: key factors to ensure in the food industry

In the food industry, product safety does not depend solely on processes or cleaning protocols. Equipment design, particularly conveyor design, is a key factor in preventing contamination risks and enabling effective, repeatable cleaning. Conveyors and modular belts are in direct or indirect contact with food for much of the process, which is why their design…

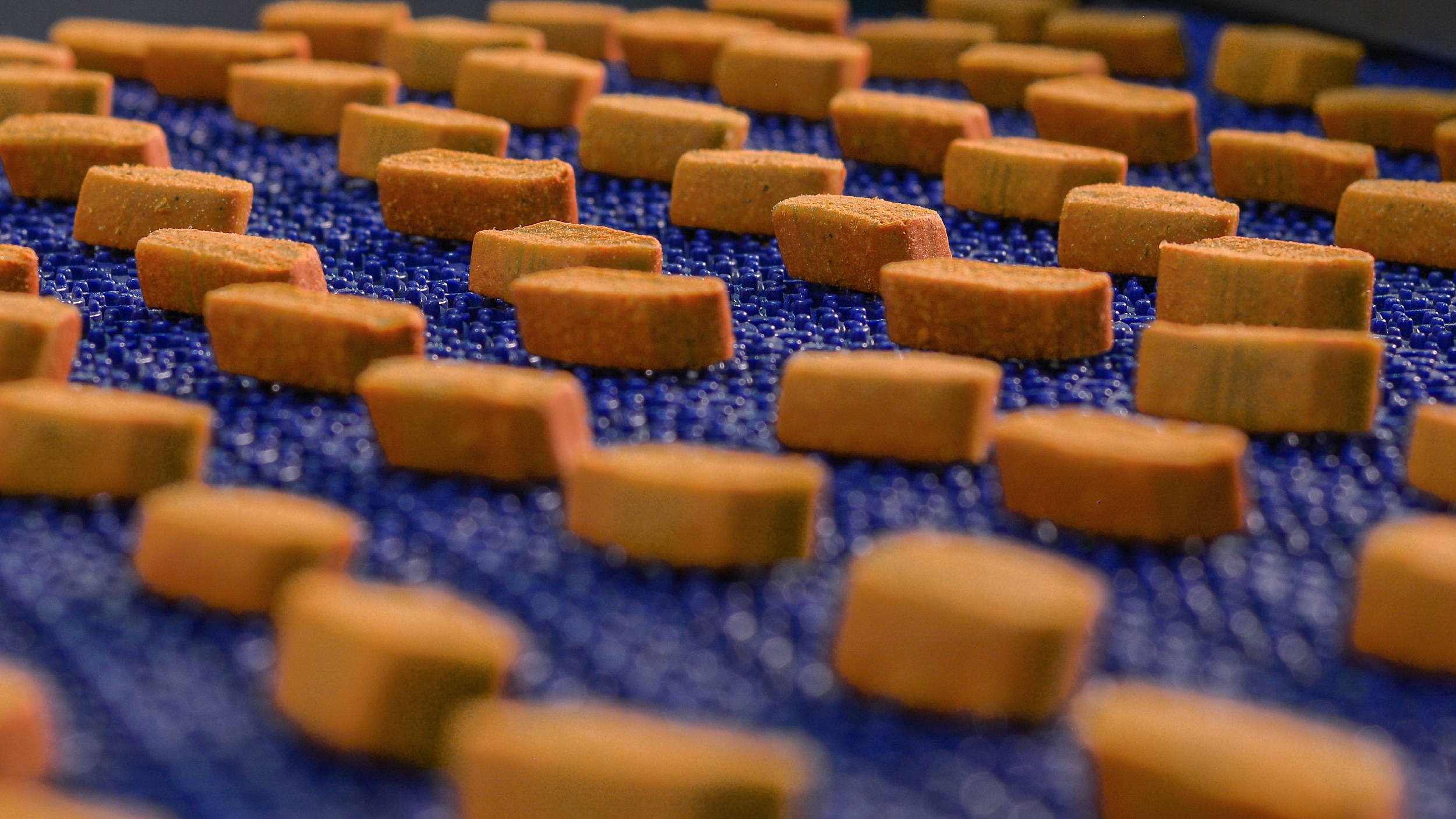

C12 Nub Top: Non-stick solution for sticky products

Highly demanding food-processing applications—such as handling frozen, coated, wet, or sugared products—share a common challenge: preventing the product from adhering to the belt. To address this issue, Eurobelt introduces the C12 Nub Top Series, a non-stick, open-surface modular belt that combines technical performance with advanced hygiene. Its 12 mm (0.47 in) pitch design includes micro-protrusions…

From rollers to modules: why plastic modular belts are the most efficient solution

In recent years, industrial plants have accelerated the replacement of metal roller conveyors with plastic modular systems. The reason is clear: greater safety, less maintenance, and a significant reduction in operating costs. What problems do traditional roller conveyors bring with them? Roller conveyors include multiple wear points—bearings, chains, lubricants, and pulleys—that require constant maintenance and…

Do you know which modular belt you need?

An expert will draw up a customised quotation to get your modular belt up and running on your production line as soon as possible.

Any doubts? Solve them here.

Check the most frequently asked questions about Eurobelt’s plastic modular belts and the sectors we serve.